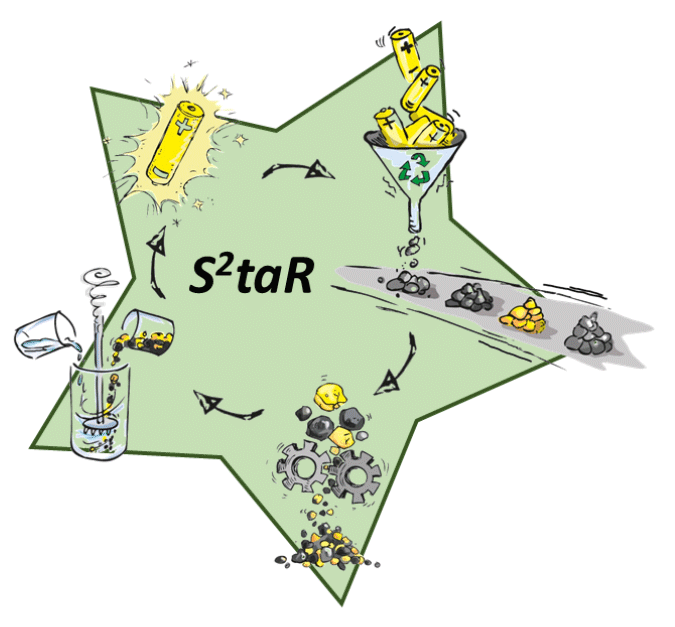

S2taR – Development of All-Solid-State Battery Recycling Processes

Recycling of battery systems represents a key aspect in order to complete the value-added life cycle of batteries. For conventional battery systems, i.e. systems based on lithium-ion batteries (LIB) with liquid electrolyte, various approaches have been already developed in the area of mechanical, thermal, chemical and metallurgical processes. The overall aim is to recover the raw materials and return them to the value-added chain of battery manufacturing via resynthesis processes as well as after-use concepts. In addition to LIB based on liquid electrolytes, lithium-ion batteries based on solid electrolytes and lithium-metal or lithium-free anodes, generally referred to as all-solid-state batteries (ASSB), will most likely come onto the market in the coming years. At the current state, it is unclear, especially with regard to the used solid electrolyte (polymers, sulphides, oxides) and the choice of anode, how well ASSB can be recycled and which sub-steps need to be added to existing recycling processes for LIB. Furthermore, the possibilities of resynthesizing recovered materials and transferring them to new ASSB are to be investigated and evaluated.

Within this framework, the main goal of the project S2taR is to investigate and evaluate existing ASSB concepts regarding recyclability. In particular, the use of recycling technologies developed within the cluster for conventional LIB will be evaluated and, in the sense of a circular economy, the potential of reusing the recovered materials in ASSB will be derived in the form of recommendations for action. The results will contribute to considering recycling potentials already in the ongoing development and to promoting the commercialization of ASSB technology. In addition, the outcomes will assist to give insights into the influence of ASSB cell design (selection and design of materials, components and their combination). The sustainability of the different cell designs, especially with regard to a circular economy, will be intensively considered and evaluated in S2taR.

Through the interdisciplinary cooperation of partners with competences in the fields of material development, electrode and cell production, recycling and life cycle assessment (LCA), important questions on the topics of recyclability and sustainability of innovative ASSB can be answered at an early stage. Thus, the direction of development can be set for a higher level of recyclability and sustainability of this future-oriented battery technology before the market is further developed. The work in S2taR will support the participating research fields within the competence cluster with previously unavailable knowledge about the recycling of future battery technologies. Furhtermore, the consideration of the requirements for ASSB recycling routes can provide added value for the current development of industrial recycling processes for conventional LIBs by designing them at an early stage.

Through the interdisciplinary cooperation of partners with competences in the fields of material development, electrode and cell production, recycling and life cycle assessment (LCA), important questions on the topics of recyclability and sustainability of innovative ASSB can be answered at an early stage. Thus, the direction of development can be set for a higher level of recyclability and sustainability of this future-oriented battery technology before the market is further developed.

The work in S2taR will support the participating research fields within the competence cluster with previously unavailable knowledge about the recycling of future battery technologies. Furhtermore, the consideration of the requirements for ASSB recycling routes can provide added value for the current development of industrial recycling processes for conventional LIBs by designing them at an early stage.

Contact

Fraunhofer Institute for Surface Technology and Thin Films IST

Sabrina Zellmer

Bienroder Weg 54 e, 38108 Braunschweig

Duration of project

01.01.2021 – 31.12.2023

Involved partners