BatMix – Quantitative assessment of the future raw materials mix for battery production

The increase and optimization of battery production are closely linked to the EU’s climate targets, in which batteries play a key role. Batteries are indispensable both as intermediate storage for the stabilization of decentralized power grids, as well as for the implementation of electromobility. Due to their high energy density, lithium-ion batteries (LIBs) are currently the most important commercially available battery type for these applications. Various studies therefore predict rapid growth in this sector.

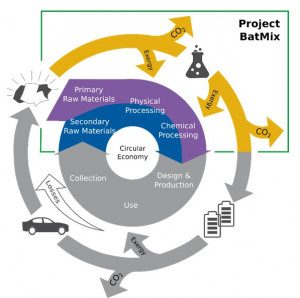

An important issue is that most of the raw materials used in LIBs (lithium [Li], cobalt [Co], nickel [Ni], graphite and manganese [Mn]) are currently obtained from the mining of primary mineral deposits. This leads to an increased carbon footprint. Increasing the recycling rates of the raw materials used could provide a potential solution to this prohblem. However, the rapid growth in consumption places tight limits on possible recycling rates. The reason for this is that the amount of recyclable material does not depend on the volume of current annual production, but on the production of previous years, as well as the service life of the products. For example, a recent DERA study estimated that even by 2050, no more than 10% of the Li used in LIBs is likely to come from battery recycling.

The goal of this project is to create probabilistic and statistically robust scenarios for the availability of battery raw materials, as well as the associated CO2 emissions and exergy consumption, and how they are likely to evolve up to 2050. The results will be used to identify the greatest efficiency potentials at the beginning of the supply chain, and thus pinpoint the most important starting points for future research projects to further optimize the “Green Battery”. The project will focus on Li, Co, Ni, Mn and graphite, all of which are critical starting materials for LIB production.

The first step will be to quantify how much of each raw material can be obtained from secondary sources, and how much must be provided from primary raw materials through mining. The respective mass flows will then be further subdivided by types (geological deposit types for primary raw materials, recycled materials/battery types for secondary raw materials). The synthesis of this information from existing data sets on battery materials, projected consumption trends in battery production, and exploration and technology trends in primary raw material extraction will be done using Monte Carlo simulations. This should allow not only for the identification of the most likely developmental trends, but also the estimation of the associated statistical uncertainties.

The data obtained in this way will then be used to calculate and a detailed breakdown of the associated CO2 balances and exergy consumption. For this purpose, the project BatMix will work closely with the other sub-projects of the “Recycling & Green Battery” competence cluster, which use Life-Cycle Analysis (LCA) to produce the necessary data for various extraction processes from primary and secondary raw materials (e.g. SIMTEGRAL). Finally, recommendations for the future extraction of battery raw materials as well as related research will be derived from the overall results.

Contact

Helmholtz-Zentrum Dresden-Rossendorf (HZDR) – Helmholtz Institute Freiberg for Resource Technology (HIF)

Dr. Max Frenzel

Chemnitzer Str. 40, 09599 Freiberg

Duration of project

01.02.2021 – 31.01.2024

Involved partners