DemoSens – Digitalisation of automated disassembly and sensor-based mechanical treatment of lithium-ion batteries for high-quality recycling

During the DemoSens project, the recycling of lithium-ion batteries from electric vehicles, hereafter LIB, is to be digitalised and automated along the entire process chain from disassembly to sorting to mechanical processing. Up to now, the disassembly of LIBs is carried out manually and with a low disassembly depth (e. g. removal of the cable harness). Battery modules and cells that have been exposed and crushed for material separation are then processed using classic separation methods such as sifting and screening. In the DemoSens project an automated disassembly with the help of robots and sensor-based mechanical processing will be carried out for the first time. For this purpose, an iterative and mutual adjustment of the process steps disassembly and mechanical treatment will take place.

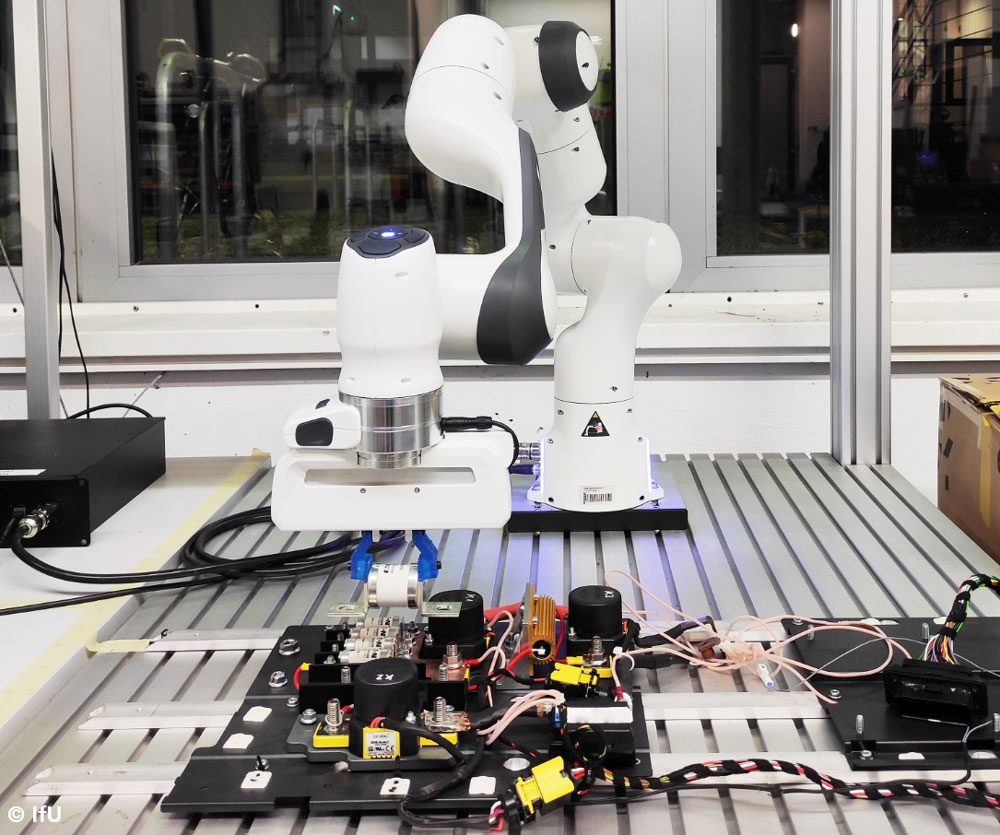

As part of the project, a robot system for large-volume and heavy components will be set up in a pilot plant, which will be able to carry out disassembly down to module/cell level using optical sensor systems and various separation processes. In order for the robot to be able to carry out the corresponding work steps independently and in a self-regulating manner, precisely fitting machine learning methods are being developed. Sensor-based identification of battery system components during disassembly allows to separate them into defined fractions, making subsequent recycling processes more flexible and efficient. The dismantled fractions as well as storage components of the batteries (modules / cells) are characterised (after mechanical processing) with the help of sensor-based systems and sorted into appropriate fractions for optimised recycling. In the process, the effects on the subsequent metallurgical processing of the active materials will be evaluated through ongoing material characterisation and modelling of pyro- and hydrometallurgical processes.

For the project as a whole, the heterogeneity of the LIB components, as a result of a wide variety of designs and material combinations, represents a major challenge for recycling. This will be met, among other things, by a labelling system (e.g. using RFID chips or QR codes) and suitable (sensor) techniques for identification and sorting (e.g. image recognition with subsequent mechanical separation systems, etc.).

Contact

FH Münster – Institute for Infrastructure, Water, Resources, Environment (IWARU)

Prof. Dr.-Ing. Sabine Flamme

Sigrid Hams

Corrensstr. 25, 48149 Münster

Duration of project

01.10.2020 – 30.09.2023

Involved partners